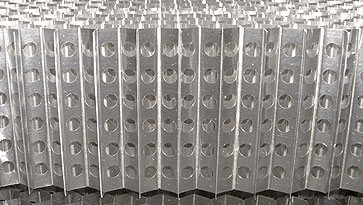

The use of aluminium honeycombs in the construction of wind blade moulds is a good solution because these materials allow good air circulation through the moulds

The perforated macro honeycomb has a transverse perforation that allows a flow of liquids or gases to pass through the entire structure evenly. At the same time, the honeycomb structure provides rigidity and support.

Energy from lightness

The uniform diffusion of a heated air stream is often crucial for the hardening of a wind blade part, which is why the macro-perforated honeycomb is used in moulds for large components such as wind turbine blades.

High-performance materials such as polypropylene and high-density foams such as PET and PVC can be used for the turbine components themselves.

Related products

LIABILITY DISCLAIMER: The above data are to the best of our knowledge correct and are intended to give information about our products and their potential applications. No warranty is given or implied in respect of certain properties of the products or their suitability for a particular application. We reserve the right for technical changes without further notice. We guarantee impeccable product quality under our terms of sale.

Already know what you want? Use our configurator

Go to configurator